A multislide bender is a metalworking machine tool used in the high-volume manufacture of stamped components from wire or strip.

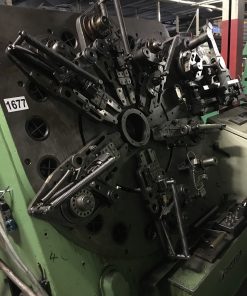

Rather than moving in an up-and-down motion, as with punch presses, multislide machines work at right angles, allowing tooling to access the metal from many directions and stamp or bend the metal from multiple sides — either sequentially or simultaneously — in order to produce bent or twisted items. Items such as flat springs, spring clips, brackets, connectors, friction plates, shunts, and collars are often manufactured using this technique.

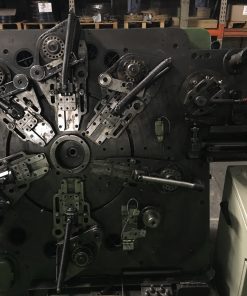

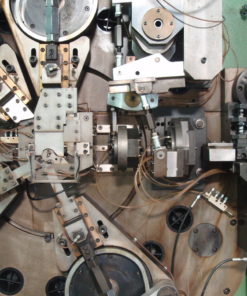

As their name suggests multislide benders feature slides, which are traditionally actuated by cams and now by servo motors on some modern equipments.

Unlike other traditional processes, multislide stamping techniques can produce complex shapes and bends at highly cost-efficient prices. Because multislide stampings use less material in the manufacturing process, less material is ultimately wasted. This then translates to lower material costs, which can be especially important when manufacturing components from more expensive materials.

Because the dies in these wire and stripe forming machines are capable of so many different motions, manufacturers are afforded great flexibility in adapting their product design to fit current market-demand, while still allowing for high-volume production at a rate of almost 300 pieces per minute.